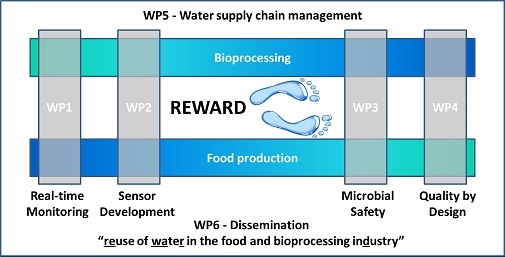

Reuse of water in food and bioprocessing industry (REWARD)

PROJECT IS COMPLETED

Project period: 2014 – 2018

The REWARD project will put Danish processing and measurement equipment businesses at the forefront of modern process water management practice.

REWARD is going to establish a research community that will provide the basic knowledge to bring Danish industry closer to self-sustainability - the closed factory principle - where water intake is diminished by re-using production streams.

This will provide the Danish food and bioprocessing industry, already challenged by productivity and outsourcing problems, with a leading edge and will put Danish processing and measurement equipment businesses at the forefront of modern process water management practice.

REWARD focuses on process water cases from the food and bioprocessing industries with multi-product lines and includes technology providers working with generic principles adaptable to other industries with related challenges such as the brewing industry, vegetable/fruit processing, bio-refineries and the fermentation industries.

Water is not only a resource, it is a life source. We all share the responsibility to ensure a healthy, secure and sustainable water supply now and in the future for our communities, environment and economy – our life depends on it.

The massive volumes of process water wasted in the food and bioprocessing industries represent an environmental burden that can be turned into a resource.

The main aim of this project is to reduce water consumption in the food and bioprocessing industries. We hypothesize that on-line sensor-based monitoring and “fingerprinting” of process water quality will lead to far more intelligent utilization of process water.

REWARD objectives are

• Maximizing reuse of process water and minimizing intake of potable water without compromising safety by implementing Process Analytical Technology and Quality by Design methodologies

• Introduce active real-time measurement based monitoring and control regimes of process and cleaning water for enhanced production and/or cost reductions in a sustainable way using dairy and fermentation processes as a model system and implementing the methods in full-scale production with the industrial partners

• Enable real-time monitoring of the chemical and biological water quality and equipment surfaces by employing novel in-line spectroscopy and developing nano-technology based measurement principles

• Forming a strategic research project and a knowledge platform between leading universities, major service providers and the industry aimed at solving problems related to water reuse by introducing new state-of-the-art technologies and methodologies

- University of Copenhagen, Denmark (coordinator)

- Technical University of Denmark, Denmark

- Technical University of Munich, Germany

- DHI Group, Denmark

- Arla Foods Ingredients, Denmark

- Novozymes A/S, Denmark

- DSS, A Tetra Pak Company, Denmark

- Niras A/S (former Alectia A/S), Denmark

- LiqTech International A/S, Denmark

Funded by:

Project: Reuse of water in the food and bioprocessing industries - REWARD

Period: 1st of January 2014 - 30th of September 2018

Grant donor: Innovation Fund Denmark and Mælkeafgiftsfonden

Grant size: DKK 12.749.313

FOOD grant: DKK 90468,000

Total budget: DKK 26,468,000

Contact

Søren Balling Engelsen

Søren Balling Engelsen

Professor

Food Analytics and Biotechnology