High-quality and sustainable fish feed production

PROJECT IS COMPLETED

Period: 2014 -2018

This project aims to improve the extrusion process to optimise the use of raw materials and the quality of fish feed

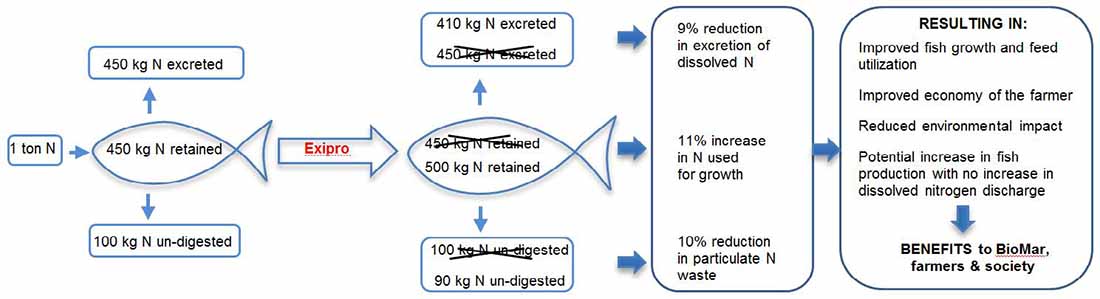

Globally, aquaculture is the fastest-growing food-producing sector, and hence there is an increasing need for fish feed. Fish require a specific ratio of digestible protein to grow, but proteins are among the most challenging raw material in feed production due to strong competition with livestock production and the human food industry. An imbalanced protein intake leads to increased amino acid catabolism, i.e. the loss of the most valuable nutrient ingredient, and an increased load of nitrogen compounds to the environment.

The production of high-quality nutrient-dense fish feed requires extrusion of the ingredients into the feed. The extrusion process can, however, alter and deteriorate the nutritional quality of the proteins. Currently, the extrusion process is based entirely on empirical learning. Knowledge of the chemical reactions and physical processes that happen inside an extruder is limited.

The hypothesis is that there is a link between extrusion-induced protein changes at the molecular level and nutritional responses and fish growth.

Fishmeal is the preferred protein ingredient in fish feed due to its high protein content and well-balanced amino acid profile. However, to support sustainable aquaculture production, fishmeal is increasingly being replaced by alternative protein ingredients, which may contain anti-nutrients and differ in their amino acid profile. Feed may be formulated using a blend of various protein sources, and is often supplemented with crystalline amino acids to fulfil the essential amino acid requirements.

Protein denaturation during extrusion is one of the most important protein-related reactions, and it triggers structural mobility involving other protein reactions. Denaturation causes the enzyme-accessible sites of a protein to become exposed, and the irreversible denaturation, degradation and formation of disulphide bonds will occur. Consequently, the availability of proteins may decrease.

The aim is to overcome the undesired changes to proteins at the molecular, nutritional and biological levels during extrusion by identifying the mechanisms that cause the chemical and physicochemical changes during feed extrusion.

By linking an understanding of protein changes during extrusion to feed utilisation and fish growth, methods for producing high-quality fish feed can be established and applied in the production line.

ExiPRo has received 4 year funding from the Danish Council for Strategic Research. However, the council has been closed down and strategic research is now a part of Innovation Fund Denmark.

ExiPRo has received 4 year funding from the Danish Council for Strategic Research. However, the council has been closed down and strategic research is now a part of Innovation Fund Denmark.

Funding: DKK 6,860,000

Project: New Physicochemical and Technological Approach for High Quality and Sustainable Fish Feed Production – ExiPRo

Period: 1st of September 2014 - 28th of February 2018

Contact

Vibeke Orlien

Vibeke Orlien

Associate Professor

Design and Consumer Behavior