Growing sustainable oyster mushrooms on by-products

Researchers at the Department of Food Science at the University of Copenhagen, together with three companies, are developing a food ingredient from oyster mushrooms that are grown on e.g. by-products from the beer industry. The project is an example of how food research can help make the food system more sustainable.

By research assistant Peter Nikolaj Kornum and associate professor René Lametsch, Department of Food Science at the University of Copenhagen (UCPH FOOD)

Mushrooms can absorb nutrients from many different sources and some people might be familiar with do-it-yourself kits for mushrooms that can grow on coffee grounds. Researchers from the Department of Food Science at the University of Copenhagen (UCPH FOOD) have, in collaboration with three companies, started growing mushrooms on by-products from other food industries. The goal is to develop a plant-based product for use by both the hospital system and the general consumer that is more sustainable than existing meat substitutes and contributes to a more circular food system. The research project is called “Development of plant-based products for the hospital system” and the product will be a mixed-plant product, comprised in part of the oyster mushrooms and the by-products from the food industry on which the mushrooms are grown.

Easily digested and packed with good amino acids

Many would like to contribute to a better climate and a good option is to eat a more plant-based diet to reduce your carbon footprint. Therefore, we want to find a cultivation method for a plant-based meat substitute product made from oyster mushrooms that tastes good, is produced sustainably and is nutritionally advantageous compared to many other plant-based products. The product will be for the general public, but with such good digestibility and amino acid profile that it can also be used as a vegan alternative to meat in the hospital system.

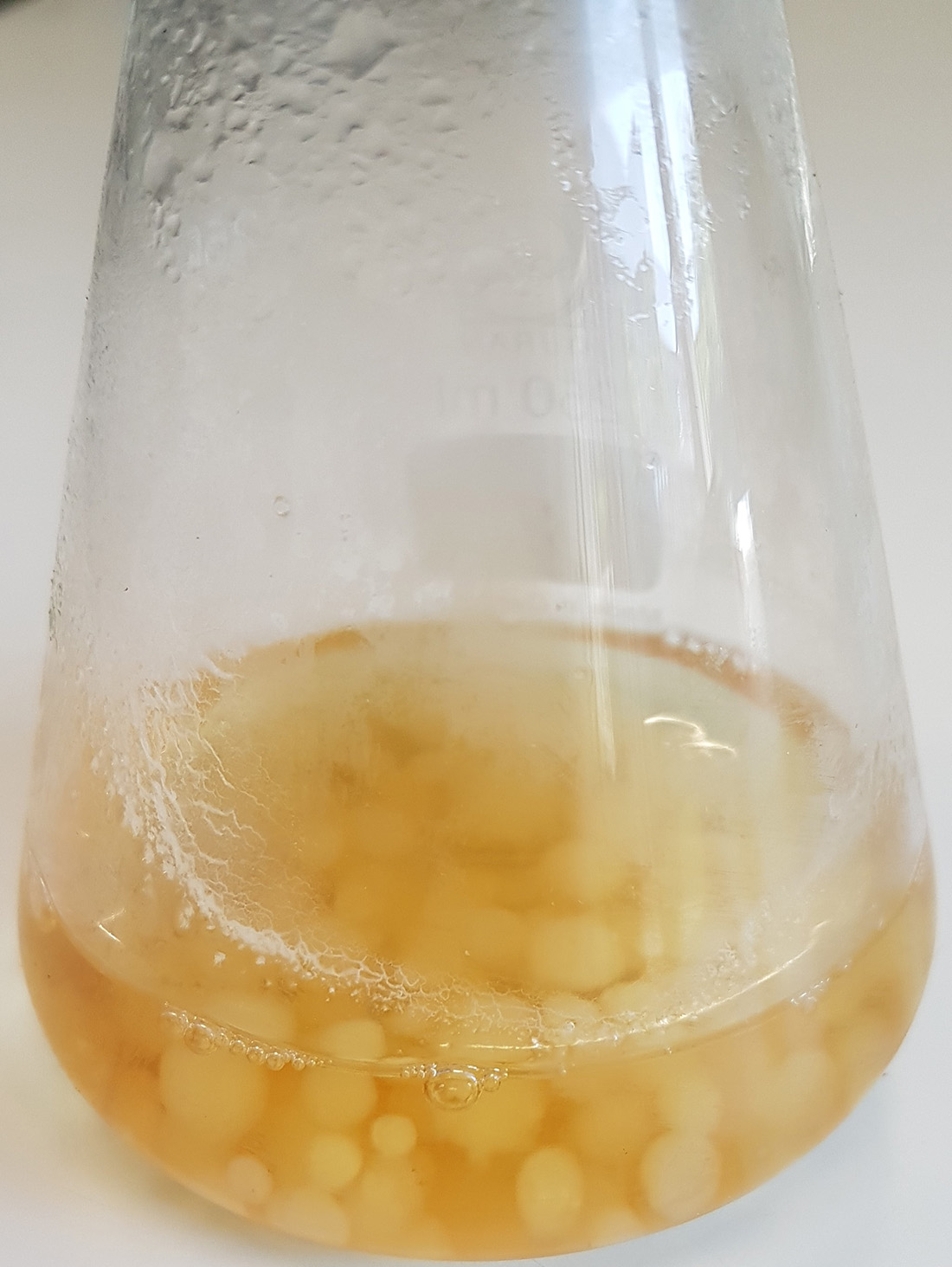

As mentioned, we hope to find a much more sustainable cultivation method than other plant-based alternatives use and we use only by-products for the cultivation, which is done by liquid fermentation in tanks – what is called vertical cultivation. Other plant-based products typically occupy large areas of agricultural land. The by-products that we use are pre-processed and will require minimal treatment to be used as a substrate for the mushrooms. At the same time, our product will be a composite product comprised of mushroom mycelium and by-products and we will be able to utilise a large amount of by-products while also generating very little or no waste products. It is dried to a powder and this is the final product. Thus it is a food ingredient that can be used in other products, including, for example, meat substitute products.

Finished ingredient comprised of brewers spent grain (BSG) from beer production and mushroom mycelium. Picture: UCPH FOOD.

Mange plantebaserede erstatningsprodukter indeholder en eller anden form for planteprotein, fx sojaprotein eller ærteprotein. Vores produkt vil have tilsvarende funktionalitet og vil derfor kunne tilføjes til mange køderstatningsprodukter, hvor der både er brug for protein, samt indhold som giver tekstur til produktet. Vores hypotese er, at fermenteringen af restproduktet via svampene vil lede til et produkt som ernæringsmæssigt er af en langt højere standard end det oprindelig restprodukt.

Great potential for food waste

There are already examples of products that contain fungal protein and utilise fungal fermentation, but these existing productions often use more expensive or less sustainable sources as substrates for the mushrooms. In this project we use brewers spent grain (BSG), which is a by-product from beer production, as well carrot residues as substrate for the mushrooms. Large quantities of by-products are produced by the food industry and with regards toBSG; huge amounts are produced by the beer industry (approximately 39 million tonnes worldwide and the BSG represents 85% of the waste product in beer production). The BSG has low economic value in itself and is sold, for example, as animal feed, which is not the most sustainable use.

A great deal of the time up until now has been spent exploring exactly which conditions provide the mushrooms with the best opportunity to grow in order to generate as much product as possible. As the project progresses, a number of analyses of the nutritional quality will be made and possibly also an analysis of how the process can be scaled up to very large quantities.

If everything goes as planned and we end up with a good product, we expect Planteslagterne to be able to use the product as an ingredient in their product and that the market will discover new opportunities to make the food system more sustainable with help from the research.

Topics

Related News

Contact

Research assistant Peter Nikolaj Kornum, Department of Food Science at the University of Copenhagen (UCPH FOOD), peter.kornum@food.ku.dk

Associate Professor René Lametsch, UCPH FOOD, rla@food.ku.dk

or

Communications officer Lene Hundborg Koss, UCPH FOOD, lene.h.koss@food.ku.dk

Facts about the research

The Department of Food Science at the University of Copenhagen (UCPH FOOD) has received DKK 721,000 for the project “Development of plant-based products for the hospital system”. The project is an innovation project under UCPH FOOD, which has also financed the project (link) and is being done in collaboration with the companies MicroBiota Food ApS, Planteslagterne ApS and GulerodsGruppen A/S. The project started on 1 October 2019 and will run through the end of 2020.