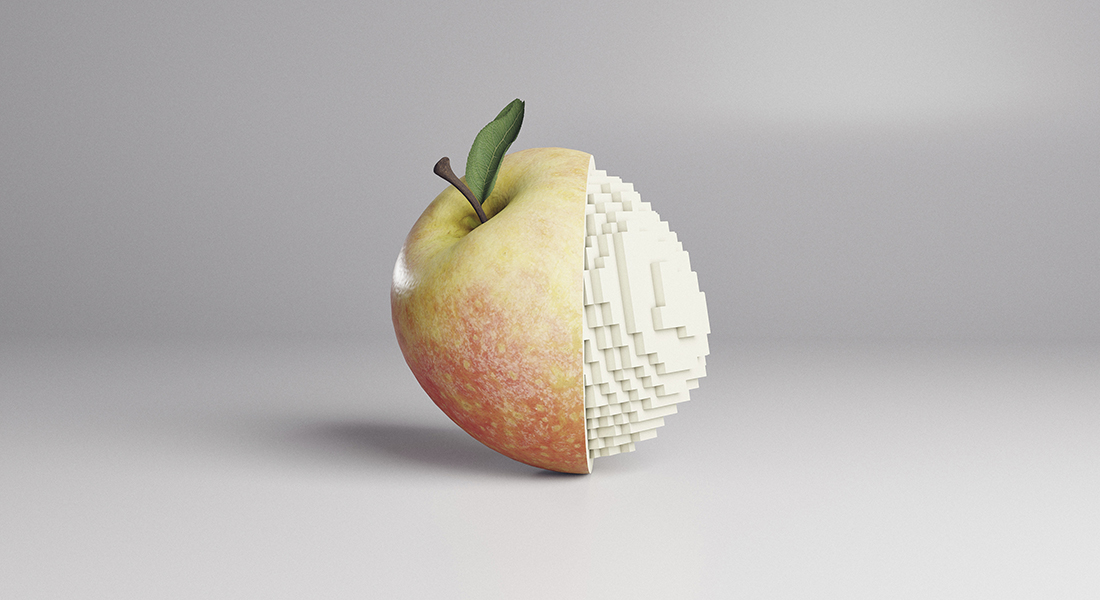

Digitalisation and modelling of food systems

In order to inspire future green food production systems with a low environmental footprint, we at UCPH FOOD deploy front-edge data and sensor technology for digitalization and optimization of food production and the food value chain.

This research area uses data analysis to measure properties and functionalities from raw materials to end-products in order to optimize and characterize food production and end-quality in sustainable ways while maintaining strong industrial competitiveness.

This is widely applied for raw material identification, process monitoring, and optimization, food fraud and adulteration detection, gastronomy, understanding the biology of fermentation, flavor research, proteomics, metabonomics, and many other areas.

The basic research in this area utilizes technologies such as remote sensing, quality by design, process analytics, process modelling, machine learning, chemometrics, artificial intelligens, and robotics. Through these technologies, it is possible to solve complex problems and uncover completely new phenomena.

The aim is not only to perform predictive performance but also to better understand the food system and how we might alter food production techniques to be more sustainable.

Learn more about UCPH FOOD’s digitalization processes at our Chemometrics research field.

Contact:

Rasmus Bro

Rasmus Bro

Professor

Design and Consumer Behavior

Frans van der Berg

Frans van der Berg

Associate Professor

Ingredient and Dairy Technology

Morten A. Rasmussen

Associate Professor

Microbiology and Fermentation

Åsmund Rinnan

Åsmund Rinnan

Associate Professor

Ingredient and Dairy Technology

Søren Balling Engelsen

Søren Balling Engelsen

Professor

Food Analytics and Biotechnology